Foil stamping is an increasingly popular finishing technique used in modern printing and packaging. The ability of foil stamping to add visual impact through shine, texture, and visual heightening would be impossible with traditional methods of printmaking. The primary users of foil stamping are luxury brands that want their products to be perceived as superior through the creation of high-quality packaging and branding to attract and inspire customers.

In today’s retail environment, the packaging of a newly purchased product may be the first physical contact that a customer has with the brand. According to a recent survey conducted by Ipsos, 72% of all respondents reported that packaging design has a strong influence on their purchase decision.

As a result, foil stamping will not only assist in positioning the brand more visibly in the retail space but also in making the brand more imagable. It provides a sense of prestige that is greater than what the printed word can do. Thus, it will continue to build trust in the brand and perceived quality of the product. Let’s discuss in detail.

What is Foil Stamping?

Foil stamping is both a printing and a finishing method. Essentially, it employs the combination of heat, pressure, and foil (either metallic or pigmented) to transfer a decorative image onto a surface. This process results in the application's very thin layer of foil, which can be glossy, matte, or textured depending on the desired effect.

Also, foil stamping has other names like foil hot stamping, foil pressed printing, or hot foil stamping, which vary with different methods used.

Difference Between Foil Stamping And Regular Printing

Normal printing uses ink that soaks right into the paper. It's fine for most things, but the finish is flat. Foil stamping is different. It uses foil, not ink. They use heat to press the foil onto the surface. This makes a cool design that really pops.

Foil stamping makes sharp, shiny designs. It can give a gold or silver look, or even a textured feel. The finish is smooth and raised. Ink can not do that. That is why you see foil stamping on fancy packaging and special designs.

History and Evolution of Foil Stamping

-

How Foil Stamping Started

Foil stamping has been around since printing began. At first, it was a hands-on way to put gold leaf on books, often for fancy covers. Artists would even do the work themselves. This was how they decorated important religious books and royal papers. As printing got better, hand-gilding slowly turned into machine stamping.

-

Foil Stamping in Modern Packaging

In the last century or so, foil stamping machines have become more rapid, more efficient, and cheaper. Metal foils started to be used by packaging manufacturers for items such as cartons, labels, and boxes. Now, foil stamping is a common thing that premium packaging services provide all over the world.

How Foil Stamping Works?

Here is the full guide on the foil stamping process:

-

Step-By-Step Foil Stamping Process

- A custom metal die is created with the desired design.

- Foil is placed between the heated die and the substrate.

- Heat and pressure activate the adhesive layer on the foil.

- The foil transfers onto the material where the die presses.

-

How Heat, Pressure, and Dies Work

The heat from an oven is necessary to soften the adhesive of the foil. Pressure applied to the foil will provide a clean transfer to your substrate, while your dye color will provide the final shape and detail on your project. All three components must be monitored to ensure future success.

-

Hot Foil vs. Cold Foil

Hot foil stamping uses both heat and pressure. And the Cold foil uses a UV glue. It skips the heat. Each method suits different designs and quantities.

Types of Foil Stamping

The following are some types of foil stamping:

-

Hot foil stamping

Hot foil stamping is common because it creates sharp and durable results on materials.

-

Cold foil stamping

Cold stamping is quicker, so it often appears in big print jobs. It can handle super fine details, but only on flat stuff.

-

Digital foil stamping

Digital foil stamping means you don't need metal dies. It is great for only a few copies.

-

Micro-embossed foil stamping

This type of foil stamping combines tiny raised patterns with foil. It adds depth and interest to it.

Common Types of Foils Used

Some of the common types of foil are:

-

Metallic foils

Gold and silver are big hits, making things look fancy and shiny.

-

Pigment foils

This gives solid, matte colors. That is perfect for a simple and modern look.

-

Holographic

Hologram foil creates cool and color-shifting effects, moving with the item.

-

Pearlescent foils

These give a soft, shimmery look without being too loud.

-

Matte and gloss foils

Matte foils look classy but simple, and gloss foils brighten things up.

-

Specialty and textured foils

These include brushed, leather-look, and patterned foils.

-

Scratch foils

Scratch foils are often used for security applications like vouchers and promotional cards.

Foil Stamping Materials Compatibility

-

Paper and paperboard

Foil stamping works exceptionally well on coated and uncoated paper stocks.

-

Cardstock and specialty papers

Textured and premium papers enhance foil adhesion and visual depth.

-

Corrugated boxes

Foil stamping can be applied to corrugated packaging with proper surface treatment.

-

Leather

Leather foil stamping is widely used for luxury goods and accessories.

-

Plastics

Certain plastics accept foil stamping using specialized foils.

-

Synthetic

Synthetic papers provide excellent durability and foil adhesion.

-

Fabrics

Foil stamping is used on fabric labels and decorative textiles.

Foil Stamping in Packaging and Printing

-

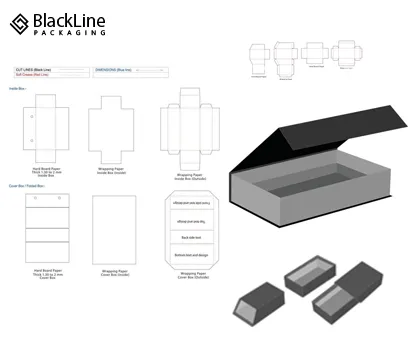

Use in custom packaging boxes

Foil stamping is one of the methods that custom packaging boxes use to make logos, brand names, and important details more visible.

-

Application in luxury retail packaging

High-end brands consider foil stamping as one of the means to express exclusivity.

-

Business cards, labels, and stationery

Foil stamping gives a printed substance the aura of being professional and the quality of being distinct at the same time.

-

Cosmetic, food, and gift packaging

Foil stamping is a contributor to the shelf appeal and brand recognition of products in competitive markets.

Key Benefits of Foil Stamping

Foil stamping provides a number of benefits. Some of them are:

-

Increases Perceived Value

Products with foil finishes feel worthy. They are often valued as premium and luxurious.

-

Enhances Brand Identity

Foil stamping reinforces brand recognition through consistent visual elements.

-

Elevates Visual Appeal

Foil stamping instantly catches light and attention, making designs stand out.

-

Versatile Design Options

Foils come in versatility. They are available in many colors and finishes.

-

Wide Range of Finishes

There are endless finishing options available.

-

Adds Security

Holographic foils can stop fake products.

-

Durable & Protective

Foil does not fade easily and resists wear.

-

Eco-Friendly

Modern foils can be recyclable and low-waste.

-

No Ink Needed

Foil stamping reduces ink usage, supporting cleaner production.

Foil Stamping vs Other Printing Techniques

-

Spot UV & foil stamping

Spot UV provides contrast through gloss. And the foil stamping provides contrast through the shine of the metal.

-

Foil stamping vs embossing and debossing

Foil stamping adds shine. And embossing adds depth.

-

Foil stamping vs digital printing

Digital printing is versatile, and foil stamping is luxurious.

Design Considerations for Foil Stamping

The following are Important Design Considerations when designing a Foil Stamp for a product.

- The color of the logo should be the basis for selecting the foil stamp color. Besides, the textural/visual properties of the foil material should be taken into consideration as well when deciding the foil color. Gold and silver are the standard foils, while holographic and matte foils are the modern ones.

- The designer also needs to take the container into account and the materials used to make the container (for instance, plastic, metal, cardstock, etc.).

- The colour of the container and its tactile appeal are two major aspects in foil stamp designing.

Environmental Impact

-

Eco-friendly Foil Options

It is true that nowadays, plenty of foils rely on aluminum as their primary component and therefore, have very little wastage.

-

Recyclability Considerations

Usually, foil-stamped paper can be recycled together with other types of paper and does not need separation at all.

-

Packaging Trends

According to Smithers, sustainable packaging demand is growing at over 6% annually. So, the Foil stamping could become a favorite choice.

Industries That Use Foil Stamping

In industries, foil stamping is commonly used in:

- Luxury packaging

Used for expensive stuff to make it look cool and attract customers.

- Makeup and Skin Care

Often seen on fancy skincare packaging to show off brand names and important stuff.

- Electronics

Applied to device boxes to show quality, innovation, and trust.

- Automotive

Used on interior trims and packaging to add a refined and polished finish.

- Corporate branding

Used on business stuff like folders, cards, and presentation boxes to make a strong brand image.

- Pharmaceutical

Helps make labels on medicine packaging secure, clear, and professional.

- Food and Drinks

Common on wine, fancy food, and special products to give them a classy look.

- Jewelry and fashion packaging

Adds beauty and style to boxes, tags, and gift packaging.

Choosing The Right Partner

The right foil stamping partner is very important.

- First, check out their experience. A good partner should have a solid portfolio and know-how about different foils, materials, and stamping methods.

- Next, think about quality control. You want even heat, pressure, and lining up to get a clean foil look without mess-ups.

- Also, make sure they know the rules for packaging, mainly for food and medicine. A smart partner will get industry rules and safety, so you won't have problems or have to reprint stuff. That way, you get good results you can depend on.

Blackline Packaging is a trusted and authentic packaging supplier that offer unlimited customization options.

Future Trends in Foil Stamping

Foil stamping is evolving with innovative and clever concepts. Digital foil facilitates the printing of small orders and custom designs easily. Brands can incorporate names or special features without the need for cumbersome tools. While this is taking place, smart packaging is also on the rise. Foil combined with QR codes enables customers to scan and watch videos or get product information. The latest biology-friendly foils consume less metal and energy.

Conclusion

Foil stamping is, without a doubt, one of the best methods to boost the aesthetic of any kind of packaging material. Thus, the process would certainly create an irresistible package that would help your brand to be identified with a high-quality product and let the consumers know they are purchasing a luxury item.

With the increasing adoption of eco-friendly materials along with the development of new technologies, foil stamping is being modified in response to the prevailing trends in the packaging industry. The brands that are in search of a high-end method for showcasing their products will find foil stamping to be a timeless and flexible choice.

Using foil stamping from Blackline Packaging, you can get a unique and attractive package for your brand. Our experienced foil stamping specialists will work with you to create packaging that is not only visually stunning but also has a lasting impression on the customers. From the beginning to the end, let us be your partner for packaging. Contact Blackline Packaging, and we will help you make your products more noticeable.

Frequently Asked Questions

We've answered all the common questions you may have before ordering a custom box.

What is stamping foil made of?

It is made up of layers of polyester film, a release coating, color, and glue.

Is foil stamping the same as embossing?

Nope. One just makes the area shiny. The other makes it raised.

What are the four types of metal stamping?

They are blanking, bending, coining, and embossing.

What is foil stamping in printing?

It's when foil gets moved onto something using heat and pressure.

Is foil stamping the same as hot stamping?

Hot stamping is the same as foil stamping.

What materials can be foil stamped?

Things like paper, cardboard, leather, plastic, and some fabrics.

Is foil stamping costly?

It costs more to make than ink printing, but it's worth the money.

Can foil stamping be good for Earth?

For sure. Today's foils can follow recycling and low-waste rules.

How is foil stamping different from Spot UV?

Spot UV makes the area bright. And foil provides a metallic look.

Does foil stamping fade over time?

No, the foil marking process is extremely resistant and long-lasting.