Cardboards are everywhere. We find it on cereal boxes, shipping boxes and even milk boxes. It is powerful, light, and recyclable. It is used to package and protect products by many companies. It is paper-based and in various forms.

Others are hard and stiff, whereas others are brown and elastic. Cardboard is also environmentally friendly, and it minimizes wastage. It is applied in the houses, shops, and plants. It is unbelievable that one single material can have so many functions in our lives.

Cardboard is used in everyday packaging solutions in small and large boxes to cartons. Numerous brands worldwide rely on it to provide customers with security in delivery. This blog is talking about cardboard and its origin.

Overview

Cardboard is a hard paper substance. It is applied in the manufacture of boxes, cartons, and packaging. It is more robust than ordinary paper. It can carry heavy stuff and ensure their protection during transportation. Pulp and fibres are used to produce cardboard.

It is a packaging material that is very popular. It is dependable and cost-effective, therefore applied in many industries. It assists products to remain damage-free. The cardboard is easily moulded, folded and printed to be used as creative packaging designs.

Brief Look At Cardboard As A Sustainable Material

Cardboard is environmentally friendly and is manufactured using trees and recycled paper. It decomposes readily and does not pollute nature. Recycling of cardboard helps to reduce waste. It is an ecological packaging liked by many individuals and businesses.

It belongs to a circular economy which fosters reuse. It is possible to recycle cardboard seven times, and then it is not so strong. It is eco-friendly, therefore suitable for green packaging. This is the reason why most brands are substituting plastic with cardboard.

What Is a Cardboard?

Cardboard is a robust product of paper. It is applied in packaging and production. It is heavier than paper and is layered. The cardboard boxes are designed to store and protect. It is used in many industries.

Additional durability can be provided to cardboard. There are those that are grease-resistant or waterproof. It is flexible and will suit almost any packaging requirement. It supports numerous industries, and this includes electronics and food.

Cardboard definition refers to a heavy paper packaging. It consists of fibres and pulp. It may be one-layered or multi-layered. Paperboard boxes, cartons and containers are made with it. It is strong and flexible.

It is easy to process and print, and this is why it is preferred by manufacturers. It provides strength and style in presenting the products. Cardboard is flexible, which has granted it the ability to shape and design.

Difference Between Cardboard, Paperboard, and Corrugated Board

- Corrugated cardboard is layered and is used to ship. Both are generically referred to as cardboard. Each type has its own use. They vary in terms of thickness and strength.

- Paperboard provides sophistication, whereas corrugated board has the advantage of protection. They are important in various stages of packaging.

How Cardboard Combines Strength, Flexibility, and Recyclability

Cardboards can bend without breaking. It is also easy to recycle. This renders it ideal to be packaged. It safeguards products and is environmentally friendly. This is why it is utilized by many companies. It contains an ideal balance in terms of rigidity and softness. It is shock-absorbing due to its layered structure.

The History and Evolution of Cardboard

The usage of cardboard has a history of more than one century. It began as plain paper packaging. It grew stronger and more useful with the course of time. Corrugated fibreboard began to be manufactured at factories to be used in shipping.

Today, it is used in many ways. It continues to change and evolve ideas. The initial cardboard box was introduced in the 19th century. It soon substituted wooden crates with lighter and less expensive ones. Contemporary technologies have increased the use of cardboard. It is an essential element of world trade and packaging design today.

How Cardboard Is Made?

Pulp and fibres are used to produce cardboard. These are trees and recycles. The pulp is washed and effused. And then it is dried and cut into sheets. The result of this process is good and powerful cardboard.

It passes through various phases to enable it to be a completed product. Smoothness and durability are achieved through quality control. The virgin pulp is normally combined with recycled fibres to balance.

Raw Materials: Pulp, Recycled Paper, and Fibres

Cardboard starts with pulp. Pulp is an extract of trees and old paper. In order to make it strong, fibres are inserted. Recycled paper helps to conserve trees. Such materials are combined and washed. The latter are then utilized to produce cardboard.

All materials have different functions in texture and quality. Pulp that has been recycled provides eco-value, whereas the virgin pulp provides strength. They combine to form a durable packaging material. Such a mix guarantees increased performance and sustainability.

The Cardboard Production Process

-

Pulping and Fibre Processing

The pulp is made by breaking down wood or paper. Water is added to make a soft mix. Fibres are cleaned and sorted. This mix is the base of cardboard. It must be smooth and clean. This stage ensures purity and evenness in production. Impurities are removed to prevent weak spots. A balanced fiber blend results in stronger sheets. It’s the foundation of high-quality cardboard.

-

Pressing and Layering

The pulp is pressed into sheets. Layers are added for strength. Some cardboard has one layer. Others have many. Pressing makes it flat and strong. This step is very important.

Layering controls thickness and stiffness. It also determines the cardboard’s end use. Heavier boxes need more layers. Proper pressing improves texture and finish for printing.

-

Drying and Cutting into Sheets

The wet sheets are dried. Heat is used to remove water. Then the sheets are cut. They are made in different sizes. These sheets are ready for use. This step defines the final quality of cardboard. Proper drying prevents warping and damage. The sheets are then trimmed with precision. They move on to be printed or folded into boxes.

Differences Between Virgin Fiber and Recycled Cardboard Production

Virgin fiber comes from new trees. It makes strong cardboard. Recycled cardboard uses old paper. Recycled cardboard helps reduce waste. Virgin fiber is used for heavy-duty boxes. Recycled fiber reduces deforestation and carbon footprint. Virgin fiber offers better rigidity for industrial packaging. Both balance strength and sustainability. Many companies combine both to achieve the best results.

Types and Uses of Cardboard

Cardboard comes in many types. Each type has a special use. Some are thin and light. Others are thick and strong. Let’s look at the main types. Different types of cardboard serve specific needs. Choosing the right one ensures better packaging results. Some focus on looks, others on strength. Understanding them helps in selecting ideal materials.

-

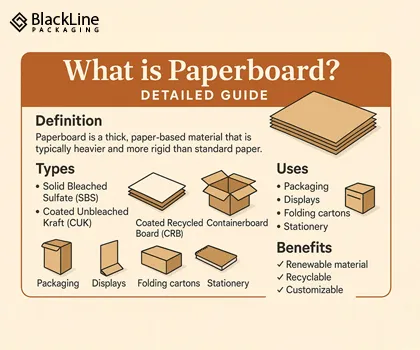

Paperboard (Single Layer)

Paperboard boxes are thin. They are used for cereal, milk cartons, and cosmetics. They are easy to print on. They are not good for heavy items. But they are perfect for light packaging.

This type of cardboard is often coated for smoothness. It is popular for branding and retail display. Its lightness makes it cost-effective. Many luxury brands use it for elegant presentations.

-

Corrugated Cardboard

Corrugated cardboard has layers. It is used for shipping and storage. It is strong and protects items. It is used for large cardboard boxes. It is also used for cardboard storage boxes. The inner fluted layer gives it shock resistance. It’s ideal for long-distance transport. Businesses rely on it for durability. It’s the backbone of the shipping industry.

-

Recycled Cardboard

Cardboard recycling is beneficial to the earth. Old paper is used to manufacture recycled cardboard. It is applied to green packaging. It is cheaper and saves trees. It is applied in reducing waste by many companies. It is also less energy and water-consuming to produce. It promotes the sustainability movement across the world. Recycled cardboard is suitable for short-term packaging. Its popularity is increasing every year.

-

Rigid Cardboard

Rigid cardboard is flinty and tough. It is applied to present gift boxes and high-end packaging. It looks nice and feels solid. It is used for special items. It is not easy to bend. It is commonly employed by luxurious brands to offer their products. It provides a classy and high-end appearance. It may be covered by paper or cloth. Its quality will add value to its product.

Where Does Cardboard Come From?

The source of cardboard is trees and recycled paper. It is made in pulp mills. These mills reduce wood into pulp. Then they prepare pieces of cardboard. There is waste paper that becomes some cardboard. It is a process that incorporates technology and sustainability. There are several countries where cardboard is produced locally. Raw materials are provided through recycling centers. This maintains the production at a constant and green level.

Sources of Raw Materials: Forests, Recycled Waste Paper, and Pulp Mills

Forests

- Forests also offer new wood, which is converted to produce pulp to make paper and packaging.

- Pine, spruce and fir are some of the trees utilized due to their strong fibres.

- Companies that practice responsible forestry do so in accordance with the sustainable forestry policies, which imply they replenish new trees after harvesting old trees.

- Forest wood provides the paper with additional power and stability, which is why numerous shipping boxes are made out of virgin fibres.

Recycled Waste Paper

- The materials found in this source are newspapers, cardboard boxes, magazines, and office paper.

- It gets gathered, sorted, washed, and re-purposed to produce new pulp to create new paper materials.

- Recycling conserves power and minimizes landfills, thus it is more environmentally friendly.

- Recycled fibre boxes come in handy in the day-to-day packaging requirements due to their affordability.

- Nevertheless, the length of recycled fibres is reduced with every application, and thus, there comes a point where recycled fibres must be combined with fresh fibres.

Pulp Mills

- Pulp mills are mills in which wood chips or paper that has been recycled are converted into pulp.

- Mechanical or chemical means are used to dissolve fibres and convert them to soft and workable material.

- The pulp mills are important as they are the ones that give raw pulp to the paper mills and the packaging manufacturers.

- Most contemporary mills set high environmental requirements to minimize the consumption of water and energy wastage.

- They are able to deal with both virgin wood and recycled wood, as per the kind of pulp required.

Environmental Organizations and Standards (FSC, PEFC)

Groups like FSC and PEFC protect forests. They make rules for using trees. Blackline Packaging follows these rules. We use safe and clean materials. This helps nature and keeps forests safe. These certifications ensure ethical sourcing. They also promote biodiversity and responsible production. Using certified materials builds customer trust.

Environmental Impact and Sustainability

Cardboard breaks down easily. It can be recycled many times. It helps reduce plastic use. Our company makes eco-friendly boxes. Cardboard leads the shift toward green solutions. It helps reduce waste in landfills. Choosing it supports a cleaner future.

Industrial and Commercial Uses of Cardboard

Cardboard is used in many places. It is used in factories, stores, and homes. It helps pack, protect, and display items. Let’s see how it is used. That’s what makes cardboard so valuable.

-

Packaging Industry

Cardboard is used to make boxes and cartons. It protects items during shipping. It is light and strong. It is used for cardboard boxes and mailers. It is the top choice for packaging.

Packaging companies rely on their strength and cost-effectiveness. It helps prevent product damage during transit. Cardboards can be customized for different needs. Its efficiency keeps it in high demand.

-

Retail and Display

Stores use cardboard for product packaging. It helps show the brand. It is easy to print on. It makes products look nice. It is used for displays, too. Attractive displays catch customer attention. Printed designs build brand recognition. Cardboard’s light weight allows easy setup and movement. It’s a favorite choice for in-store marketing.

-

E-commerce and Shipping

Online stores use cardboard for shipping. It keeps items safe. It is used for large cardboard boxes. It is strong and easy to carry. It is perfect for e-commerce. E-commerce brands depend on it for cost savings. It ensures safe delivery across long distances. Cardboard mailers and inserts improve unboxing experiences. It plays a key role in online retail success.

-

Creative and DIY Uses

People use cardboard for crafts. It can be made into furniture and toys. It is easy to cut and shape. It is used for school projects. It is fun and useful. Cardboard sparks creativity in art and design. It can be reused for eco-friendly crafts. Many artists turn it into beautiful creations. It proves that sustainability can be creative too.

Benefits of Using Cardboard

Cardboard has many good points. It is cheap, light, and eco-friendly. It is used in many ways. Let’s look at the benefits. Its benefits go beyond packaging. It supports green initiatives and brand value. It’s practical and adaptable to modern needs. No wonder it remains the top packaging material worldwide.

-

Cost-Effective and Lightweight

Cardboard is not expensive. It is easy to carry. It saves money on shipping. It is perfect for small and big items. It is used by many companies. Its lightweight nature lowers transport costs. It’s ideal for both local and global shipments. Companies prefer it for budget-friendly packaging. It delivers value without sacrificing quality.

-

Customizable and Print-Friendly

Cardboard is easy to print on. It can show logos and designs. It can be cut into shapes. It is used for branding. It helps products stand out. Modern printing techniques enhance its appeal. It’s a creative medium for marketing success.

-

Recyclable and Biodegradable

Cardboard breaks down in nature. It can be recycled many times. It does not harm the earth. It is better than plastic. It is a green choice. That’s why eco-conscious brands prefer it.

-

Versatile Across Industries

Cardboard is used in many fields. It is used in food, fashion, and tech. It is used in homes and offices. It is useful everywhere. That’s why we love it. Its adaptability keeps it in high demand. From food delivery to electronics, it fits every need. It also supports creative display and storage. Cardboard truly connects industries worldwide.

The Future of Cardboard Packaging

Cardboard is changing. New ideas are making it better. It is becoming smarter and greener. Let’s see what’s next. The future looks bright for cardboard solutions.

-

Innovations in Biodegradable and Compostable Cardboard

New cardboard can break down faster. It is made from safe materials. It helps reduce waste. It is good for the planet. We support these changes. This innovation supports global sustainability goals. It limits landfill waste and carbon emissions. More brands are investing in biodegradable packaging. It’s a big step toward a zero-waste future.

-

Digital Printing and Smart Packaging Technology

Cardboards can now have smart labels. It can show product info. Digital printing makes it look better. It helps with tracking and safety. It is the future of packaging. Smart packaging improves customer experience. QR codes and sensors are being added. These help brands engage digitally. It’s where technology meets sustainability.

-

Sustainability Trends Driving Cardboard Demand

More people want green packaging. Cardboard is the top choice. It is safe and clean. It helps brands look good. Our company follows these trends. As consumers choose eco-products, brands adapt fast. Cardboard leads this eco revolution. It’s a symbol of responsibility and progress. The demand for sustainable boxes keeps rising globally.

Conclusion

Cardboard is strong, light, and eco-friendly. It is used in many ways. It helps protect items and the planet. Our company makes custom boxes that fit your needs. You should buy boxes from Blackline Packaging to grow your brand and help the Earth. Cardboard is not just packaging; it’s innovation. It combines sustainability, creativity, and strength. Choosing the right packaging reflects brand care. With us, you can make a real difference. So contact us today!

Frequently Asked Questions

We've answered all the common questions you may have before ordering a custom box.

What is cardboard made of?

Cardboard starts as wood pulp fibers. It often uses recycled paper, too. Workers mix the fibers with water. They press and dry the mix into thick sheets. Glue is used to stick layers together.

How is cardboard different from paperboard?

Cardboard is a thick, layered material. It often has a wavy inner layer for strength. Paperboard is a single-layer, smooth, thick paper. Shipping boxes are generally cardboard.

Is cardboard environmentally friendly?

Yes, cardboard is quite environmentally friendly. It's made from renewable wood fibers. It is very easy to recycle, and most cardboard will quickly biodegrade.

Can all types of cardboard be recycled?

No, not all cardboard types can be recycled. Clean corrugated and boxboard are usually accepted. Cardboard with grease, food stains, or wax coatings often cannot be. These dirty or coated kinds must be put in the trash.

What industries use cardboard the most?

Food and drink companies use the most cardboard for packaging. Online stores use it for shipping boxes. Electronics makers use it to protect products. Moving and storage companies use it to pack items.

How is recycled cardboard processed?

It is first sorted by type and cleaned. Workers then shred it and mix it with water. This mix, called pulp, gets filtered to remove ink and glue. Finally, the clean pulp is dried and pressed into new cardboard sheets.

Why is cardboard the preferred packaging material?

It is very strong but also lightweight. This keeps products safe while lowering shipping costs. Cardboard is cheap to make and easy to customize. It is also easily recycled and better for the planet.

Is cardboard technically wood?

Cardboard is not technically wood. It starts as wood fibers or recycled paper. These fibers are processed into pulp and then pressed into sheets.