All products that you find in a store are in a box, pouch or any form of packaging. But have you ever questioned yourself as to how many boxes a business requires to order at a time? This is where the term 'MOQ' comes in. It is a simple yet powerful idea that controls how packaging is made and sold. Understanding it can help brands save money, reduce waste, and plan better.

In this blog, we are discussing what MOQ is in packaging and why it matters. When you hear “What does MOQ mean?” you might feel confused at first, but this guide will make it easy. For businesses ordering boxes or pouches, it is very important to know the meaning of MOQ in packaging.

This guide will help you understand the rules, what affects the numbers, and how your brand can find flexible options. Blackline Packaging works with many clients who ask about MOQ for custom boxes and MOQ for custom pouches. We will take you through step by step on the terms and also give you useful tips.

Understanding MOQ (Minimum Order Quantity)

The definition of MOQ as applied to packaging states that the minimum number of units that a supplier will grant in a single order is regarded as the packaging. Attempt to give a smaller order, and the supplier does not respond or offers a price per unit that is higher.

MOQs make the suppliers compensate for their expenses to maintain smooth production. They will require operating machines, purchasing materials, and compensating workers; hence, they will require producing enough units to justify it.

To explain, when you have a skincare brand and you are interested in printed pouches, the supplier can require you to order 5,000. That becomes your minimum order. If you sell subscription boxes, your supplier may set an MOQ of 1,000 boxes.

MOQ helps packaging companies reduce waste and save time. It also keeps machines running at the right speed. Without MOQs, suppliers would not be able to offer fair or stable prices to their customers.

How MOQ Works in the Packaging Industry

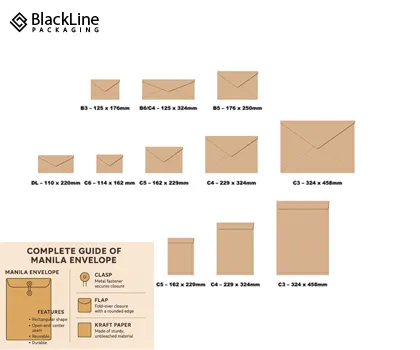

MOQ For Custom Vs. Stock Packaging

MOQ is calculated in various ways according to the type of packaging: either stock or custom.

- Ready-made sizes and designs are used in the packaging of stocks and therefore allow the supplier to produce large quantities of stock and sales of minimums.

- Brand-specific custom packaging is produced, and this requires new printing plates, new layouts, or special colors to be established. These additional processes are time-consuming and add additional costs, and the MOQ of ordering custom boxes tends to be significantly higher than that of stock.

- Custom designs also require more material preparation and labour. This is why small brands often start with stock packaging before moving to custom packaging.

Common MOQ examples

MOQ numbers can vary based on the packaging style and the production process.

- In the case of corrugated shipping boxes, the temptation of suppliers is usually 2,000 units since the machines run more efficiently at that point.

- In the case of custom printed pouches, the MOQ can be 10,000 units because of the expense of film rolls and printing equipment.

- To cover the cost of coating, lamination or embossing, rigid boxes or folding cartons with special finishes may be set at 3,000 units as MOQ.

There is less wastage of materials due to the production of bigger batches. This makes the price per unit remain low for the customers.

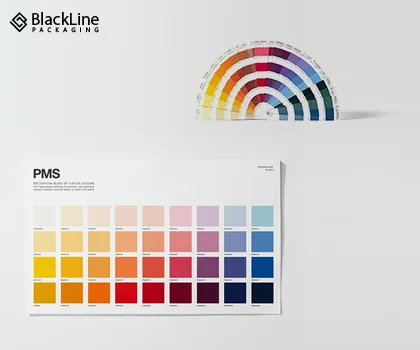

Relationship Between Material Type And MOQ

The influence of material type on MOQ is rather high since various materials need various preparation times.

- Paperboard is a material applied in folding cartons, and it usually has mid-MOQs due to its preparation, easy-cut, and easy-print characteristics.

- Eco-friendly boxes made of kraft paper normally have low MOQs since they require minimum processing.

- Flexible pouches require plastic films that require an increase in MOQs since roll sizes in machines are large.

- The premium film is shiny and called Mylar; it drives MOQ up as it is usually foil-layered with barrier protection.

The MOQ in manufacturing is further exacerbated when printing and finishing are incorporated, e.g., foiling, magnetic closures, etc. These features take additional time and equipment, which have to be compensated for by the suppliers by increasing orders.

Key Factors That Influence MOQ

There are several important factors that decide how big your minimum order quantity will be. All factors have an influence on cost, time and production setup. With these factors, you will make a more effective decision regarding your packaging requirements.

-

Customization Level

When your packaging includes a unique design, special printing, or a new dieline, the setup becomes more complex. Custom features require extra tools and printing plates, which increase production cost from the start. This raises the MOQ meaning in business, as suppliers must protect their investment.

The less your design resembles others, the larger the order of units you will probably have to make the process cost-effective. Customization increases value but raises the size of the order required to initiate production.

-

Material Type

Material plays a direct role in determining MOQ. The cost of sourcing and processing premium materials like rigid cardboard and recycled pulp is higher, and therefore, suppliers tend to demand a higher minimum order level.

When it comes to regular materials such as kraft paper or corrugated cardboard, the production will be easier at lower quantities, so that the brands will be able to make smaller orders. When a brand would like to be luxurious, then they should be prepared to have increased MOQs. Choosing basic materials is often the best path for startups that want low minimums.

-

Box Size and Complexity

The structure of your packaging also affects MOQ. A simple RSC mailer box is easy to create and needs fewer steps, so suppliers can allow smaller orders. In contrast, intricate packaging styles, such as boxes with magnetic closures or double walls, take longer to produce.

This is why magnetic boxes for luxury packaging with low MOQ options often come with higher unit requirements. As the design becomes more detailed, the MOQ must increase to cover manufacturing costs. Complexity adds both time and material usage.

-

Supplier Size and Capabilities

The capabilities of the various suppliers are different, and therefore, they change their minimums. Small suppliers can have lower MOQs, as they have smaller machines and cater to smaller brands which require flexibility.

Big factories are concerned with large-scale production; hence, the bigger the order is, the more profitable the operations. When seeking out low MOQ packaging suppliers, you must correlate your requirements with the ability of a supplier. Knowing your supplier will enable you to better handle cost and order size.

Common Types of MOQ in the Packaging Industry

There are various systems that suppliers employ to stipulate their minimum order quantities in the packaging world. Knowing these kinds of suppliers may make you select the right supplier for your business. All of those types influence cost, storage and the speed with which you can scale your brand. Understanding the difference would assist you in saving money and budgeting.

-

Unit-Based MOQ

Unit-based MOQ is the most common form used by suppliers. It implies that you are to make an order of a certain amount of goods, e.g., 1,000 boxes or 5,000 pouches. By attempting to make a smaller order, the supplier will decline it or increase the price per unit.

This model is very common in customized packaging because each run needs machine setup. It helps suppliers manage material waste and time. Businesses often choose unit-based MOQ when they want stable pricing and clear expectations. It gives brands a set number to budget for their packaging inventory.

-

Cost-Based MOQ

Cost-based MOQ is based on spending a minimum amount of money rather than a fixed unit count. A supplier may require you to spend at least $2,000, allowing you to choose fewer units if each unit is more expensive. This structure is very useful for wholesale low-MOQ cosmetic packaging or low-MOQ flexible packaging, where brands may want premium features in smaller quantities.

It gives businesses more control over their budgets. It also allows small brands to access custom packaging without committing to very high volumes. Many luxury skincare brands use this system to test their packaging before scaling up. Cost-based MOQ offers flexibility while still supporting supplier costs.

-

Pallet-Based MOQ

Pallet-based MOQ is often used for stock packaging or items that are stored in warehouses. Instead of ordering by units or cost, you order by pallet or truckload. It implies that you make a bigger commitment at any given time that small brands find difficult to handle.

It is typical of such materials as films, plastic rolls, or kraft sheets that are shipped in bulk. Pallet-based MOQ helps suppliers optimize storage and shipping. It reduces handling costs and speeds up delivery times. While it may not suit startups, growing businesses use this model to secure better per-unit pricing and faster restocking.

Strategies To Navigate Or Reduce MOQ

It is significant to know minimum order quantities, but it is even more important to know how to manage or reduce them. Small and emerging companies that do not need large amounts can also have custom packaging. By doing this through wise planning, you will be able to run the business within the budget and reduce the risks. These methods help the brands to grow smarter and quicker.

Startups & Small Businesses

Startups often worry when they see high MOQs, but there are practical ways to work around them. You can speak directly with your supplier to request custom design packaging MOQ that fits your budget. Many suppliers will agree to smaller trial orders if they see long-term potential. You can also choose simple packaging with fewer colors or finishes.

This lowers production setup costs and reduces the MOQ. Another effective strategy is sharing production runs with other brands using the same material. MOQ can be made easier to handle by planning ahead and being flexible in design. This provides small businesses with an opportunity to compete in the market without investing heavily.

Growing Businesses

Growing brands have stronger sales numbers, which gives them negotiation power. You can ask suppliers for special deals, such as ordering low MOQ skincare packaging or custom lip gloss tube packaging with low MOQ options to match your production needs. When you commit to multiple future orders, suppliers often agree to reduce the MOQ.

This gains trust and establishes a long-term relationship. Increasing businesses also have the opportunity to simplify the designs to save on the use of materials, hence the decrease in production costs. Forecasting demand and ordering in planned cycles offers better pricing. As you scale, you get more control over MOQ and cost efficiency, helping your brand stay competitive.

Conclusion

In this guide, we looked at what MOQ means, how it works in the packaging world, and what you can do about it. We covered types of MOQ in packaging and how material, design, and supplier size influence orders.

When you are a small brand or a startup, you can find an opportunity to find low-MOQ packaging providers or select low-MOQ flexible packaging runs. Once you are ready to place your order for your custom boxes or pouches, you ought to deal with a partner that you can rely on.

In Blackline Packaging, we assist brands in selecting the appropriate order quantity, material and design to ensure low cost and high quality. Let us support your brand growth. Choose our firm for packaging you can trust. Start small, test your market, then scale up with confidence. Use our packaging provider to enhance your brand or business today.

Frequently Asked Questions

We've answered all the common questions you may have before ordering a custom box.

What does MOQ stand for?

MOQ stands for Minimum Order Quantity. It is the fewest units you must buy in one order.

Why is MOQ so high for custom packaging?

When the design is unique, materials are special, or finishes are luxury, the supplier must invest more. That means the MOQ meaning in packaging is higher.

What is a typical MOQ for custom boxes?

It is dependent on design complexity, material and finish. There will be those who would order 1,000 units of simple boxes, and there will be those who will order 10,000 units of simple boxes in the event of a large number of changes or prints.

What is the difference between a high MOQ and a low MOQ?

A high MOQ means you must buy many units; it can tie up cash. A low MOQ means you can test products with fewer units. You’ll find low MOQ packaging solutions helpful for small brands.

Where can I find low MOQ packaging suppliers?

Find small manufacturers who serve small brands. Enquire of low-MOQ packaging or flexible-MOQ packaging manufacturers. Check reviews and ask for sample runs.

What does 'moq' mean in packaging?

Simply put, it is the least quantity of units that a supplier will take in a single order with your packaging.

What is the difference between SKU and MOQ?

SKU (Stock Keeping Unit) means an item that you sell (color, size variant). MOQ refers to how many units you must order from the supplier. They are different but both affect your inventory and costs.

How to calculate MOQ?

You estimate how many units you need, your budget, and setup cost, and also ask the supplier. The supplier may divide their cost by unit cost to reach your minimum.

What does MOQ mean for purchasing?

For purchasing, MOQ means you must commit to the supplier’s minimum if you want their pricing. You must plan your budget and storage accordingly.

How to set minimum order quantity?

If you are the supplier, you review your costs, machine capacity, material yields and lead time. Then you set the MOQ to cover your risk and cost.