Paperboard is a light and powerful material. It appears as paper, yet it is harder. You open it each day in boxes, cards and packages. It insures things and renders them beautiful. It can be readily printed on and workable. It is used by a great number of companies to provide food, cosmetics as well as presents. It is likewise Earth friendly, since it is recyclable.

Paperboard packaging is famous since it is easy and intelligent. It assists the brands in appearing clean and professional. We are talking about a paperboard and why this is important in this blog. Many industries make use of paperboard due to its flexibility and ease of working. It is foldable, printable and has numerous shapes.

Blackline Packaging has tailor-made packaging that is made out of paperboard and is compatible with your product. You want the box to be made of white paperboard or kraft paperboard; we have choices. Paperboard is also food safe and environmentally friendly.

Paper vs. Paperboard: What’s the Real Difference?

Paperboard is heavier and is used to package. Paper is easy to tear, whereas paperboard is not. Boxes and displays are better using paperboards. It is even stronger and more lasting. The paper is soft and flexible. Paperboard is hard and shielding. Both can be printed, but paperboard appears sharper. Food, cosmetics and gifts are packed on a paperboard.

It provides products with a clean and sanitary appearance. Paperboard is also stronger as compared to ordinary paper. It is able to withstand weight and pressure. That is the reason why it is more popular among paperboard manufacturers to use it in packaging. It is also not easily bendable or tearable. This renders it ideal for retailing and shipping.

Why Paperboard Matters in Today’s Packaging World

There are numerous paperboard industries. It contributes to the fact that the products look good and remain safe. It is easy to print and shape. We are a company that produces bespoke paperboard boxes for all types of products. The packaging made of paperboard is also environmentally friendly. Manufacturers of paperboard adore it because of its strength and style. It is ideal with food, make-up and retail products. It assists brands in the stores to shine.

Creative designs are also supported by paperboard. It is possible to add colors, textures, and logos. It makes your brand appear special and business-like. Our paperboard mailers are custom and are designed to impress. They secure your products and advertise your company.

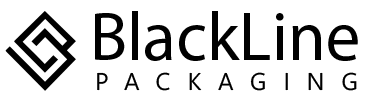

What Is a Paperboard?

Paperboard is a thick, strong paper. It is made from wood pulp. It is used for boxes, cards, and packages. It is easy to cut and fold. You can print on it to show your brand. A white paperboard box looks clean and bright. Kraft paperboard looks natural and earthy.

Paperboard packaging is used in many ways. It is light but strong. It is perfect for custom paperboard mailers and retail boxes. Paperboard is also used in schools and offices. It is found in folders, covers, and signs. It is strong enough to hold items but light enough to carry.

How Is Paperboard Made?

Paperboard starts with trees.

Step 1: The wood is turned into pulp.

Step 2: The pulp is cleaned and pressed into sheets.

Step 3: These sheets are dried and rolled.

Step 4: Some sheets are coated to make them smooth. Others stay rough.

Step 5: The sheets are cut into sizes.

Step 6: Then they are ready for printing and packaging.

That’s how custom paperboard packaging is made. Blackline Packaging uses safe and clean methods to make strong paperboard.

The process also includes checking for quality. Each sheet is tested for thickness and strength. Coated sheets are used for printing. Uncoated sheets are used for inserts. This helps us create the best custom cardboard boxes for your brand.

Physical Features That Make Paperboard Special

-

Thickness

Paperboard is thicker than paper. It comes in many sizes. Thin paperboard is used for cards. Thick paperboard is used for boxes. The thickness helps protect items inside. It also makes the box feel strong. You can choose the thickness based on your product.

Thin boards are good for light items. Thick boards are better for heavy items. Thicker paperboard also helps with stacking. It keeps boxes from collapsing. It adds a premium feel to packaging. Our company offers many thickness options. You can pick what works best for your product.

-

Rigidity

The paperboard is stiff and holds its shape. It does not bend easily. This makes it good for packaging. It keeps products safe and neat. Rigid paperboard looks professional. It is used for displays and cartons. It helps your brand look strong.

It also protects fragile items. Our company offers rigid paperboards for many uses. Rigid paperboard also helps with printing. It keeps the surface flat and smooth. This makes colors pop and text clear. It is perfect for custom paperboard boxes. Your design will look sharp and clean.

-

Weight

The paperboard is light but strong. It is easy to carry and ship. Even big boxes made of paperboard are not heavy. That’s why wholesale cardboard boxes are popular. Light packaging saves money. It also helps with transport.

Paperboard weight depends on GSM. You can choose the right weight for your needs. Lightweight paperboard is also good for mailing. It reduces shipping costs. It is easy to handle and store. Our custom paperboard mailers are made with the right weight. They protect your items and save you money.

Types of Paperboard You Should Know

-

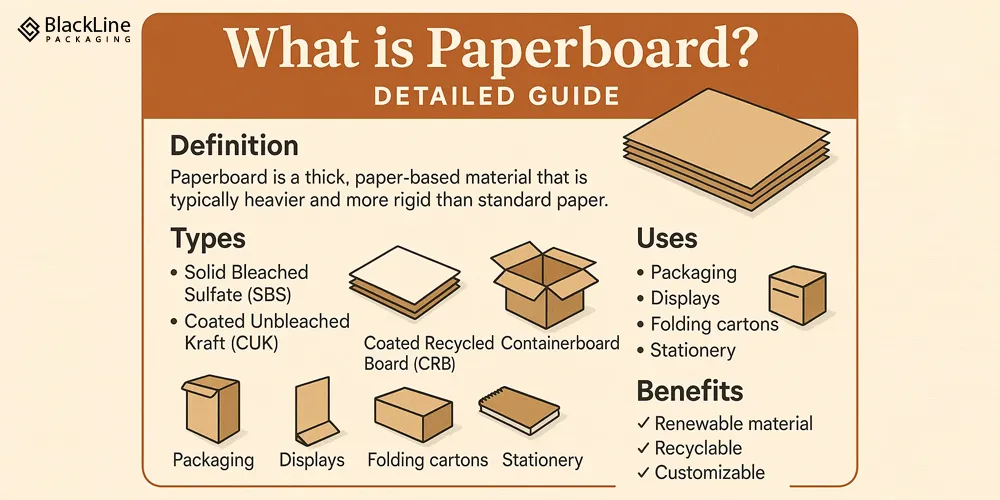

Solid Bleached Sulfate (SBS)

SBS is white and smooth. It is great for printing. It is used for food boxes and cosmetics. It looks clean and bright. It is made from bleached wood pulp. SBS is safe for food contact. It gives a premium look. It is perfect for luxury packaging. Blackline Packaging uses SBS for high-end boxes.

SBS is also easy to fold and cut. It holds its shape well. It is used in custom paperboard packaging for retail and gifts. It adds value to your product. It makes your brand look elegant.

-

Coated Unbleached Kraft (CUK)

CUK is brown and strong. It is coated for printing. It is used for drinks and frozen food. It is tough and safe. CUK is made from unbleached wood pulp. It has a natural look. It is good for heavy items. It resists moisture. It is used in food and beverage packaging.

CUK is also eco-friendly. It uses less bleach and chemicals. It is strong enough for rough handling. Our company uses CUK for durable packaging. It keeps your products safe and fresh.

-

Coated Recycled Board (CRB)

CRB is made from recycled paper. It is coated for printing. It is eco-friendly. It is used for cereal boxes and toys. CRB helps save trees. It is cheaper than a virgin board. It is good for light items. It prints well. Our company uses CRB for budget-friendly packaging. CRB is also great for colorful designs. It holds ink well. It is used in custom paperboard boxes for retail. It supports green packaging goals.

-

Uncoated Recycled Board (URB)

URB is also recycled. It is not coated. It is rough and natural. It is used for inserts and trays. URB is good for inner packaging. It is strong and eco-friendly. It is not shiny but still useful. It is used in industrial packaging.

It is a smart choice for bulk items. URB is also cost-effective. It uses less processing. It is perfect for simple packaging needs. Our company offers URB for large orders. It helps you save money and reduce waste.

Comparison Table of Paperboard Types

|

Type |

Appearance |

Strength |

Eco Impact |

Common Uses |

|---|---|---|---|---|

|

SBS |

White, smooth |

Medium |

Low |

Food, cosmetics |

|

CUK |

Brown, coated |

High |

Medium |

Drinks, frozen food |

|

CRB |

Mixed, coated |

Medium |

High |

Toys, cereal |

|

URB |

Brown, rough |

Low |

High |

Inserts, trays |

Each type has its own look and use. SBS is best for printing. CUK is strong and natural. CRB is eco-friendly and prints well. URB is rough but useful.

Grades and Calipers: Understanding Paperboard Sizes

In choosing the paperboard to use in packaging or printing, it is necessary to know about grades and calipers. The two factors will dictate the weight, thickness of the board and its overall performance.

The grades are the type and coating of the board, and the physical property of the board is determined by the caliper and GSM. The selection of the combination would make your packaging functional and attractive.

What Is GSM?

GSM is an abbreviation that is used to denote the weight of the paperboard, which is expressed in grams per square meter. The greater the GSM, the thicker the board is, the denser it is, and usually stronger. It is one of the main aspects that defines the sturdiness of the material that will be used to package. GSM is also used in the board handling during printing and folding.

Low GSM boards bend more easily and can be folded with ease, whereas high GSM boards have greater longevity and a tearing-resistant quality. It also affects the adhesion of ink on the surface, which is very important in high-quality and vibrant prints. By choosing the appropriate GSM, you will make sure that your package fits in terms of appearance as well as construction.

What Is a Caliper?

The thickness of the paperboard is called a caliper and is in points of where one point is a thousandth of an inch. Thin boards are usually between 10 and 12 points, and thicker boards may also be up to 24 or more. The role of caliper on the board is rather important in the way the board feels and plays. The larger the caliper, the greater the rigidity and protection, particularly when it comes to heavy or delicate objects.

It also influences the board folding and creasing which is vital in terms of structural integrity. In order to optimize the use of their machine, printers usually apply caliper measurements to set up the machine. Learning callipers enables you to pack your product safely and professionally.

Common Grades

Paperboard is available in different grades, each being applicable in different applications.

- C1S (coated one side) is perfect in cases when it is only required to have a shiny surface on the outside of the box.

- C2S (coated two sides) is ideal on cards and other printed materials that need a shiny look on both sides.

- The SBS (Solid Bleached Sulfate) is a high-quality white board applied in cosmetic and luxury packages.

- CUK (Coated Unbleached Kraft) is strong and has a natural brown inside, hence it is excellent for packaging food.

- CRB (Coated Recycled Board) is a friendly, environmentally conscious and economical alternative.

All grades influence print quality, stiffness, and even appearance, and thus the selection of the appropriate grade is dependent on your product and branding objectives.

Choosing the Right Thickness for Packaging Types

- Weight of the product: Thick paperboard will be needed to keep heavier products straight as they do not bend or tear. To illustrate the point, a glass perfume bottle should be packed in a stronger manner in comparison to a lightweight soap bar.

- Design: Folded, die-cut or embossed designs can require a lighter weight board that is more flexible to ensure accuracy and prevent cracking.

- Print finish: Foil stamping or UV coating are high-quality finishes and thus better applied to smoother and denser boards. Select an appropriate texture on the surface that you would like to appear on.

- Budget: Thicker boards are more expensive as more materials are used. Determine balance strength and cost-effectiveness depending on your packaging agenda.

Applications of Paperboard

Packaging Industry

- Food boxes: The food boxes are used in cereal boxes, frozen food trays, as well as takeout boxes. Food safe and often coated to be moisture resistant.

- Cosmetic packaging: Perfect use with creams, perfumes and makeup sets. Comes with high quality looks and security.

- Retail packaging: This is applied when dealing with electronics, apparel and accessories. Branding and shelf appeal.

Printing & Marketing

- Greeting cards: Paperboard offers a strong foundation to decorative prints and embellishment.

- Business cards: Provides the business with a professional touch and can withstand regular usage.

- Book covers: Book covers are applied to paperback and hardcover books, which give them structure and quality print.

Industrial Uses

- Inserts: Kimono products are kept in boxes and are secure.

- Cartons: List of shipping or storing bulk packaging, commonly employed in logistics.

- Displays: POSS and promotional crashes consisting of heavy, printable board.

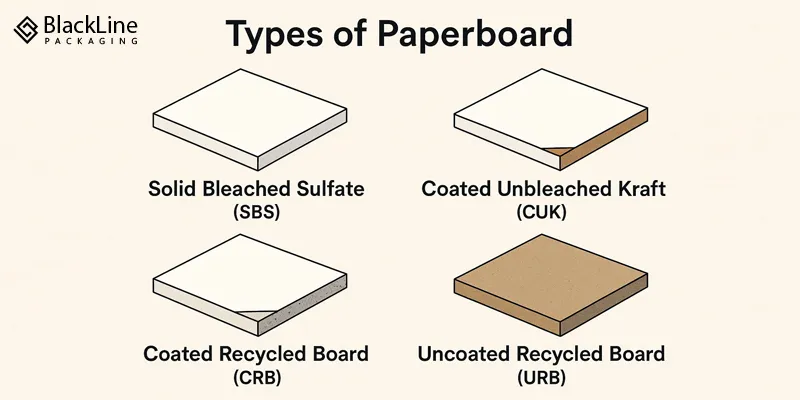

Paperboard has the following benefits

- Lightweight but strong: Portable and easy to carry, but will safeguard products.

- Wonderful to be printed and customized: Branding with vivid colours, textures, and finishes.

- Recyclable and biodegradable: Environmentally friendly and minimizing landfill waste and carbon footprint.

- Economical to use in bulk packaging: Reduced production and transportation expenses than heavy materials.

Comparing Paperboard and Other Materials

Paperboard vs Cardboard

- Paperboard: Smoother, thinner, more printing and retail package.

- Cardboard: Thicker, rough, basic box and shipping.

Paperboard and Corrugated Board

- Paperboard:)- This is suitable as packaging for lightweight retail and cosmetic products.

- Corrugated Board: It is more powerful, with fluted layers to cushion it, to be used in shipping and heavy-duty packaging.

Plastic Packaging vs Paperboard

- Paperboard: Biodegradable and printable.

- Plastic: Waterproof, durable and non-biodegradable and not as sustainable.

Sustainability Paperboard

- Wood pulp is made of renewable wood.

- Most municipal systems can recycle easily.

- It biodegrades naturally as opposed to plastic.

- Usually made with less amount of energy and less water consumption than synthetic materials.

Choosing the Right Paperboard for Your Packaging

Weight of product: The heavy ones require a thick and more rigid board.

Design: Complex folds or shapes can use flexible boards.

Print finish: Select board to match finish of choice (e.g., matte, gloss, foil).

Budget: The thinner boards are more affordable but can affect the durability or look.

Ideal Paperboard Types

|

Product Type |

Recommended Paperboard Type |

Why It Works |

|---|---|---|

|

Cosmetics |

SBS (Solid Bleached Sulfate) |

Smooth, premium look, great for printing |

|

Food |

CUK (Coated Unbleached Kraft) |

Strong, moisture-resistant, food-safe |

|

Retail |

FBB (Folding Box Board) |

Versatile, printable, cost-effective |

|

Luxury Goods |

Rigid Box Board or laminated SBS |

High-end feel, excellent durability |

Conclusion

The future of packaging is paperboard- smart, strong and sustainable. It is a combination of utility and fashion that assists in your brand shining, keeping your products safe. It is environmentally friendly and can be printed, which is why its eco-friendly nature is in line with the current values of consumers.

Paperboard is the solution whether you require boxes, cards or custom mailers. Our company will be providing customized solutions to any needs, including design and delivery. Select Blackline Packaging to take it to the next level of your packaging and surprise your customers with each unboxing process.

Frequently Asked Questions

We've answered all the common questions you may have before ordering a custom box.

What is paperboard made of?

Compressed wood pulp is used to make paperboard, or recycled paper fibre is used. It has a smooth surface that is suitable for printing and packaging.

How is paperboard different from cardboard?

Paperboard is well polished and slimmer, whereas cardboard is rougher and tougher. Paperboard is more appropriate for detailed graphics and light products.

What are the main types of paperboard used in packaging?

These include SBS (Solid Bleached Sulphate), CUK (Coated Unbleached Kraft) and recycled board. The types are different in packaging requirements depending on the strength and finish.

Is paperboard environmentally friendly?

Yes, it can be recycled and biodegradable and can be produced using sustainable materials. It is preferred by many brands in a bid to minimise effects on the environment.

What thickness of paperboard is best for boxes?

Its thickness is between 12 pt and 24 pt under the demand of a product on weight and protection. The boards will be thicker to have more durability for heavy items.

Can paperboard be recycled?

Yes – most paperboard can be recycled using the common paper recycling systems. This makes it a smart decision as green packaging.

What are common uses of paperboard in printing?

It is popular in the packaging, brochures, labels and custom printed boxes. It is smooth in nature and hence finishes well in terms of colour and design.

How strong is paperboard compared to corrugated board?

Paperboard is not very strong but can be used in light products and good printing. Corrugated board is more suitable in shipping and heavy security.

Is paperboard suitable for food packaging?

Yes, especially when they are coated or are put to the food safety requirement. It is popular on cereal boxes, snack packs and frozen food cartons.

Why do brands prefer paperboard for custom packaging?

It is cheap and easy to print on, and it gives products an upmarket look. Also, it assists the brands to be distinctive in terms of colourful and neat designs.