Packaging is not merely a box. The first thing that people see when receiving a product is it. It depicts the brand, secures the item and renders it attractive. However, it is planned before a box is made. That plan is called a dieline. It is like a roadmap which tells where to cut, fold and position artwork. In its absence, the box could not fit and appear right. Dielines assist designers and printers in collaborating. They ensure that everything is in line.

This guide is the beginning of any package, given starting with a pizza box dieline to a soap box dieline. In this blog, we will discuss the definition of a dieline and its significance. You will know how it works, how it is made and how it makes packaging look great.

What does the term “dieline” mean in packaging and printing?

A drawing that is flat and demonstrates the way a box or a package should be created is called a dieline. It informs on what to cut, fold and glue. Imagine it is a kind of outline of a colouring book. It is used by the designers to insert logos, colors and text. Printers use it to understand where to cut and fold.

The meaning of dieline is easy to use; it is a guide that assists in making packaging correct. In its absence, the box could end up being the incorrect size and shape. A box dieline assists in ensuring that everything fits well. It is applied to any packages such as cardboard box dieline, CD sleeve dieline and so on. Dielines are applied in our company to ensure that all boxes are tidy and tough.

Why dielines are essential in custom packaging design

One will require precise custom packaging. When the design is erroneous, the box will not be effective. Dielines ensure that the artwork and folds are placed as desired. They assist in preventing errors and wastage of time. A box may neither close nor the print may be crooked without a dieline template. Dielines are used by our team to ensure that each package appears great and functions correctly.

Dielines also assist the brands to be able to demonstrate their style. They present packaging in a clean and professional way. Dielines are used to ensure that we get it right, whether it is a playing card box dieline or a popcorn box dieline. In Blackline Packaging, we never consider making packaging complete without a dieline.

Brief History Of Dielines In Modern Printing

Dielines have been long-drawn by hand. Planning of boxes was done using rulers and pencils. It required much time and effort. The computers aided in creating dielines quickly as printing was improved. We now use programs such as Adobe Illustrator to design dieline templates. The tools assist us in designing such boxes as soap box dieline and pizza box dieline easily.

Dielines have become an enormous packaging component, and they are employed in each stage. They assist in creating boxes which are powerful and attractive. Our company has up-to-date tools that enable us to make dielines in a very fast and proper manner. This assists us in providing packaging that meets all requirements.

Understanding The Basics Of Dielines

-

Definition And Purpose Of Dielines

The dieline definition is easy to understand. It makes sure the final box matches the plan. Dielines are like blueprints for packaging. They guide every step from design to print. Without them, packaging can go wrong. Our team uses dielines to make sure every box is perfect.

-

How Dielines Function As Design Templates

Dielines work like stencils. Printers use them to cut and fold the box correctly. A dieline template keeps the design safe and neat. It helps avoid printing errors. Our company uses templates for all box types. This includes the playing card box dieline and popcorn box dieline.

-

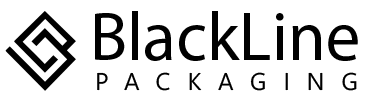

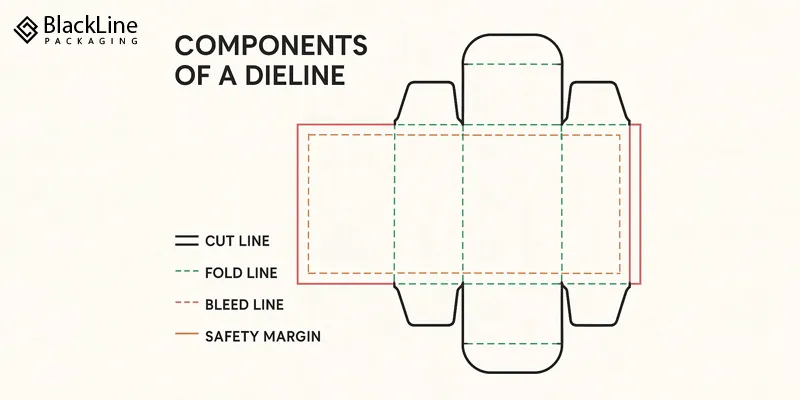

Components Of A Dieline

Every dieline has important parts.

- Cut lines show where to trim the paper.

- Fold lines show where to bend the box.

- Bleed lines make sure colors go to the edge.

- Safety margins keep text and logos safe from cuts. These parts help us make dielines for packaging, like soap box dieline and pizza box dieline.

Each part plays a role in making the box strong. We check every line before printing. This helps us avoid mistakes. Our team uses these lines to build boxes that last.

Importance of Dielines in Packaging Design

-

Ensuring Accurate Shape, Fold, And Print Alignment

Dielines help us get the shape right. They show where to fold and cut. This makes sure the box looks good and works well. A good dieline keeps the design in place. It helps the box open and close smoothly. Our company uses dielines to make sure every fold is perfect. This helps us make strong and neat boxes.

-

Preventing Design And Printing Errors

Without a dieline, mistakes happen. Text may get cut off. Colors may not match. Dielines help us avoid these problems. They guide the printer and the designer. This keeps the artwork safe. We use dielines to protect logos and text. This helps brands look their best.

-

Enhancing Production Efficiency And Precision

Dielines save time. They help printers work faster. They make sure every box is the same. This helps us make mailer boxes and retail boxes quickly and correctly. Dielines also reduce waste. They help us use materials wisely. Our team checks every dieline before printing. This helps us deliver packaging on time.

How Dielines Are Created

Common software

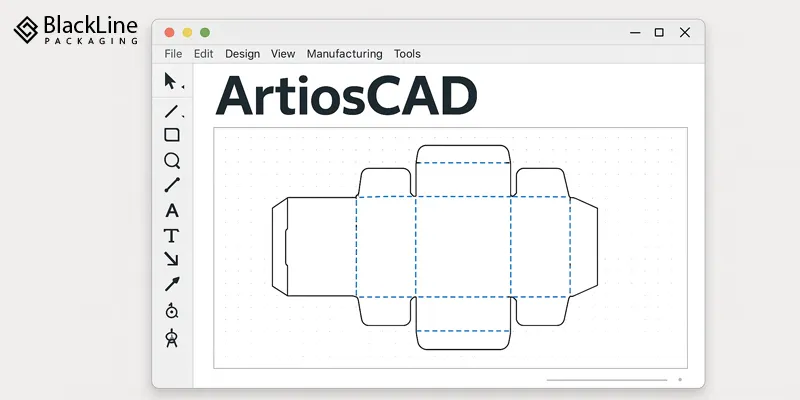

We use special tools to make dielines. These tools help us draw and plan boxes.

- Adobe Illustrator is great for drawing dielines.

- ArtiosCAD helps with 3D box shapes.

- CorelDRAW is good for simple designs.

Step-By-Step Process Of Dieline Creation

- First, we choose the box type.

- Then we draw the shape.

- We add cut lines, fold lines, and bleed areas.

- Next, we place the artwork.

- Finally, we check everything before printing.

This process helps us make cardboard boxes and rigid boxes that look perfect. We test the dieline before printing. This helps us catch mistakes early. Our team follows each step carefully. This makes sure the box is strong and neat.

Key Elements of a Dieline File

-

Cut And Trim Lines

These lines show where to cut the paper. They help make the box shape. Cut lines must be sharp and clear. They guide the machine during printing. Our team checks these lines before printing. This helps us make clean cuts.

-

Fold And Crease Indicators

These lines show where to bend the box. They help the box fold right. Fold lines must be placed carefully. They help the box open and close. Our company uses these lines to make strong folds. This helps the box stay in shape.

-

Glue Areas And Bleeds

Glue areas show where to stick parts together. Bleeds make sure colors go to the edge. These parts help the box look neat. Glue areas must be strong. Bleeds help avoid white edges. Our team checks these areas before printing.

-

Safety Zones For Text And Graphics

Safety zones keep logos and text safe. They make sure nothing gets cut off. These zones are very important. They protect the design. Our company uses safety zones in every dieline. This helps us keep the artwork safe.

Common Mistakes to Avoid When Designing Dielines

-

Ignoring Bleed And Trim Areas

If we skip bleed lines, colors may not reach the edge. This makes the box look bad. Trim areas must be clear. Bleeds help avoid white borders. Our team always adds bleed lines. This helps the box look full and clean.

-

Misalignment Of Artwork

If the artwork is not lined up, it may print wrong. Logos may be off-center. This makes the box look messy. We check alignment before printing. This helps us keep the design neat.

-

Using Low-Resolution Templates

Low-quality templates make blurry prints. We always use high-resolution dieline template files. This helps the box look sharp. Blurry prints hurt the brand image. Our team uses clear templates for every box.

-

Forgetting Structural Accuracy

If the folds and cuts are wrong, the box won’t work. We always check the structure before printing. This helps us make strong boxes. Structure is key to packaging. Our team tests every dieline before use.

Dielines and Printing Process

-

How Dielines Integrate Into Prepress Workflow

Before printing, we check the dieline. We make sure everything fits. This step is called prepress. It helps us catch mistakes early. Our team reviews every dieline. This helps us print with confidence.

-

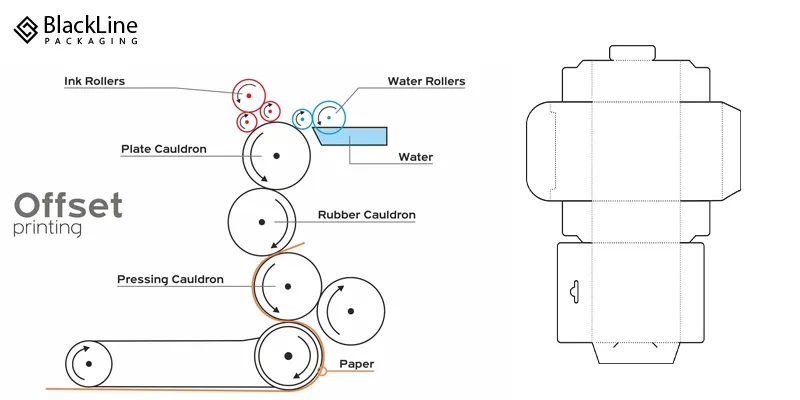

Role Of Dielines In Offset And Digital Printing

In offset printing, dielines help with plates. In digital printing, they guide the machine. Both need dielines to print right. Dielines make sure the artwork is placed correctly. They help avoid misprints and wasted materials. Offset printing uses metal plates, so the dieline must be exact. Digital printing is faster, but still needs a clear dieline to follow.

-

Checking Dielines Before Mass Production

We always check dielines before printing many boxes. This helps us avoid mistakes and save money. A small error in the dieline can ruin hundreds of boxes. That’s why we test every dieline before printing. We look at folds, cuts, and artwork placement. This step helps us deliver perfect packaging every time.

Types of Packaging That Use Dielines

-

Folding Cartons And Retail Boxes

These boxes need dielines to fold right. We use them for retail boxes and more. Dielines help us place logos and colors neatly. They also guide where to glue and crease. Retail boxes must look clean and sharp. A good dieline makes that possible.

-

Rigid Boxes And Luxury Packaging

Luxury boxes need perfect folds. Dielines help us make rigid boxes that look great. These boxes often hold expensive items. So, the packaging must be strong and stylish. Dielines help us design boxes that feel premium. They also help us keep the structure firm.

-

Pouches, Sleeves, And Labels

Even soft packages need dielines. We use them for sleeves and labels. Dielines help us place text and graphics in the right spot. They also guide the shape of the pouch or sleeve. Without a dieline, the label may not fit. We use dielines to make sure everything lines up.

-

Corrugated And Display Packaging

Big boxes need strong dielines. We use them for display packaging and corrugated boxes. These boxes often carry heavy items. So, the dieline must support the weight. It also helps us design boxes that stand out. Display packaging needs to look good and work well.

Benefits of Using Professional Dieline Templates

-

Time-Saving And Error Reduction

Good templates save time. They help us avoid mistakes. We use them for popcorn box dieline and cd sleeve dieline. Templates make the design process faster. They also help us print without errors. Our team uses templates to keep things smooth. This helps us deliver packaging on time.

-

Consistency Across Packaging Products

Templates help us make boxes that match. This is great for brands. We use them for playing card box dieline and mylar bags. Consistent packaging builds trust with customers. It also makes the brand look professional. Templates help us keep every box the same. That’s why we use them for all products.

Conclusion

Dielines are the heart of packaging. They guide design, printing, and folding. Without them, boxes may not work. Our team at Blackline Packaging uses dielines to make perfect boxes. From soap box dieline to pizza box dieline, we make sure every package is right. Dielines help us avoid mistakes and save time. They also help us make packaging that looks great. You should buy boxes from us to make your brand shine and your packaging perfect.

Frequently Asked Questions

We've answered all the common questions you may have before ordering a custom box.

What are the rules for dieline?

The rules for a dieline are accuracy, clarity, and proper separation of layers. Use different colors. And always align the dieline perfectly with your artwork.

Can I design without a dieline?

You can design without a dieline, but it is not recommended. Without it, your packaging design might not fit correctly.

What does a dieline look like?

A dieline usually looks like a flat outline of a packaging template. It includes colored lines showing where the box will be cut, folded, and glued.

What is the purpose of a dieline?

The purpose of a dieline is to guide printers and manufacturers in cutting and folding the packaging.

How do you create a dieline?

You can create a dieline using design software such as Adobe Illustrator. Start by outlining your packaging’s exact dimensions. Then mark cut, fold, and bleed lines using specific colors for clarity.

What is a sleeping line called?

A sleeping line in packaging is referred to as a fold line. It shows where the material should be folded.

How to read a dieline?

To read a dieline, identify each type of line by its color or style. Solid lines show where to cut. Dashed lines indicate folds. And dotted lines represent glue areas.

What are the 7 types of lines and their meaning?

The 7 types of line are: 1. Horizontal: meaning calm and stability 2. Vertical: meaning strength and growth 3. Diagonal: meaning movement and energy 4. Curved: meaning softness and flexibility 5. Zigzag: meaning excitement and tension 6. Dotted: meaning incompleteness or guidance