Every box has a story. It describes the way a product fits, moves and appears. We do not simply consider colors or logos when we are designing the packaging. We think about size. That’s where dimensions come in. The length, width and height dimension of a box decides how well it holds your product. When the box is small, it is not going to fit. In the event that it is too large, it could be broken when shipping. That’s why we measure carefully. We use these dimensions to make sure the box is strong, safe, and looks good. It helps us protect the product inside. It also helps us save space during shipping.

In this blog, we are discussing how to measure boxes and use these dimensions the right way. Boxes that fit well also make your brand look neat. Customers like packaging that feels right. Backline Packaging make sure every box is measured with care. It is not only about appearances, but it is also about functionality and security.

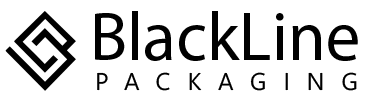

Understanding Box Measurements

-

What length means in packaging

Length is the longest side of the box. It usually runs from left to right. When you open a box, the side that stretches the most is the length. It helps us know how far the box goes from one end to the other. It’s the first number we write when listing box size. Knowing the length helps us design the box better. It also helps us plan how the product will sit inside. Our company always starts with measuring the length. It helps with stacking and storing boxes. It also helps with printing designs. We use it to make sure the box looks balanced. A well-measured length keeps the product secure and stable.

-

What width means in packaging

Width is the shorter side of the box. It goes from front to back. It tells us how wide the box is. This side is important when stacking boxes or fitting them on shelves. Width helps us know how much space the box takes up. It’s the second number in the dimension order. We use it to make sure the box fits in storage. It also helps us design labels and prints. Width also helps with product placement. It makes sure items don’t move inside. Our team checks width to keep products safe. A good width keeps the box easy to handle and store.

-

What height means in packaging

Height is how tall the box stands. It goes from the bottom to the top. Some people call it depth. But in packaging, we mostly say height. It helps us know how much space is inside from top to bottom. Height is the last number in the size order. It tells us how much room is above the product. We use it to make sure the box closes properly. It also helps us protect fragile items from damage. Height matters for stacking boxes. It also helps with shelf display. Blackline Packaging uses height to make packaging look clean. A proper height keeps the box strong and neat.

How Different Industries Use These Terms

- In e-commerce, we use dimensions to show product size online.

- In logistics, we use them to plan space in trucks and warehouses.

- In printing, we use them to design labels and artwork.

- Retail stores use dimensions to display products neatly.

- Warehouses use them to stack boxes safely.

- Designers use them to create packaging that looks good.

Our company makes sure every industry gets the right size. Using the right terms avoids confusion. It also helps with faster production. We teach our clients how to use dimensions correctly. This keeps packaging smooth and simple. Sometimes, people mix up the terms. That’s why it’s good to follow a standard.

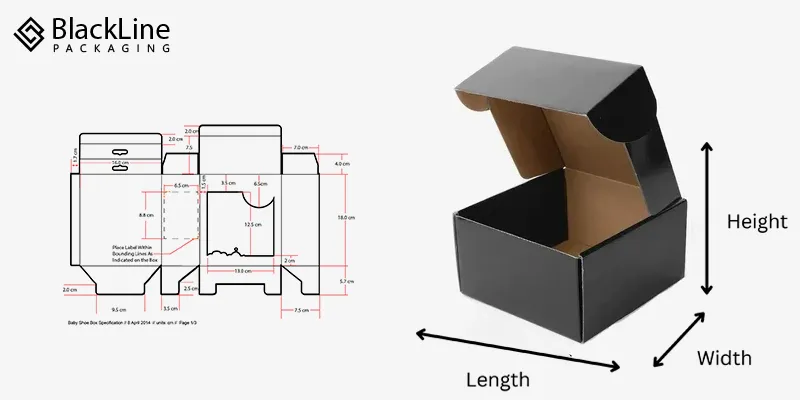

The Right Way to Write Dimensions

-

L × W × H: The Standard Order

We always write dimensions in this order: Length × Width × Height. This helps everyone understand the size clearly. It’s used by shipping companies, designers, and box makers. This order avoids confusion and mistakes. It helps us talk clearly with clients and carriers. It also helps us make boxes that fit perfectly. Our team follows this rule every time. It’s a global standard in packaging. It assists in printing and shipping. We use it to ensure that nothing goes wrong. This order keeps things easy and clear.

-

Why the Order Matters for carriers, manufacturers, and designers

In case you reverse the sequence, the box may not be suitable to your product. This order is used by carriers such as UPS and FedEx to determine the cost of shipping. Designers use it to plan artwork. Manufacturers use it to cut materials. So, getting it right saves time and money. Wrong order can lead to wasted materials. It can also cause delays in delivery. Customers may get the wrong size box. That’s why we teach our clients the correct way. It also affects how products are packed. Right order helps with stacking. Blackline Packaging uses this method to avoid errors. It keeps packaging smooth and safe.

-

Key Errors to Steer Clear Of

Some businesses write height first or switch width and length. This causes confusion. Boxes may arrive too small or too big. That’s why our company always follows the correct order. Mistakes can lead to returns and unhappy customers. They can also cost more in shipping. We help businesses avoid these problems. Our experts double-check every measurement. Clear labeling helps avoid mix-ups. We also provide guides to help. Our team supports clients with every step. This keeps packaging easy and correct.

How to Measure Dimensions the Right Way

-

Tools You Can Use

You can use a ruler, tape measure, or digital scale. For big boxes, use a measuring tape. For small boxes, a ruler works fine. Digital tools give fast and accurate results. You can also use apps to record sizes. Our team uses pro tools for big orders. We make sure every box is measured right. We also offer measuring kits. These help with custom orders. Blackline Packaging make measuring easy for everyone.

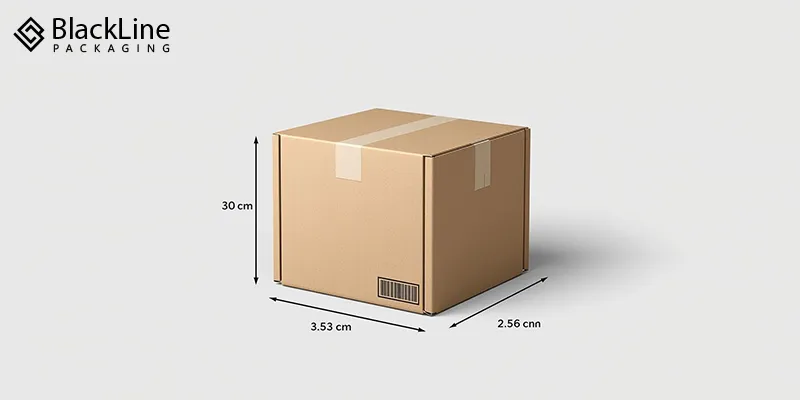

Step-by-Step Measurement Guide

-

Measuring Length

Place the box on a flat surface. Look for the longest side. Measure from one end to the other. That’s your length. Use a straight ruler for clean results. Write the number down right away. Double-check to avoid mistakes. We always begin with length. Length helps with product layout. It also helps with printing. We use it to plan the box design. This keeps the product safe and neat.

-

Measuring Width

Now find the shorter side. Measure from front to back. That’s your width. Make sure the box is closed. Use a ruler or tape for better results. Keep the box steady while measuring. Width helps us plan the box shape, stacking, and storage. It also affects how the box opens. We measure it carefully for the best results. This keeps the box easy to use.

-

Measuring Height

Close the box flaps. Measure from the bottom to the top. That’s your height. Height is easy to miss, so be careful. Use a tall ruler or tape. Write the number clearly. Our team checks height twice for safety. Height helps with product safety. It also affects how the box looks. We use it to protect fragile items. This keeps the packaging strong and clean.

-

Internal vs. External Dimensions

Internal dimensions are used to fit products inside. External dimensions are used for stacking and shipping. Our packaging experts always check both to make sure everything fits well. Internal size helps protect the product. External size helps with shipping costs. We use both to make strong boxes. Our team makes sure nothing is left out. We label both sizes clearly. This helps with packing and delivery. Our team explains the difference to every client. It keeps things simple and smart.

Why Dimensions Matter in Real Life

-

Packaging Design

When we design boxes, we use the length, width and height dimensions to make sure the product fits. We also use it to plan the artwork and printing. Good design starts with the right size. It helps the box look neat and clean. It also helps the product stay safe. Our team uses dimensions to make smart designs. Design also affects branding. The right size makes printing easier. We help brands stand out with perfect boxes. This makes packaging look great.

-

Shipping and Logistics

Shipping companies charge by size and weight. If your box is too big, you pay more. If it’s too small, your product may break. That’s why we measure carefully. The right size saves money and time. It also helps with fast delivery. We work with carriers to get the best fit. Blackline Packaging make boxes that travel well. We also help with bulk orders. Our team plans space in trucks. We make shipping smooth and easy. This helps businesses grow.

-

Retail and E-commerce

Online stores show box sizes to help customers choose. If the size is wrong, customers may return the product. That’s bad for business. So, we make sure the dimensions are correct. The correct size builds trust with buyers. It also helps with better reviews. We help online shops pick the best box. Our team checks every detail. We also offer custom sizes. This helps with special products. We supports e-commerce growth. It keeps customers happy.

Common Standards in Packaging

-

Corrugated Box Standards

Corrugated boxes come in many sizes. Some common ones are:

- 12″ × 12″ × 12″ for small items

- 18″ × 18″ × 18″ for medium items

- 24″ × 24″ × 24″ for large items

These sizes help with stacking and shipping. We follow these standards to make strong and safe boxes. Standard sizes save time in production. They also help with easy storage. Our team uses these sizes for fast delivery. We also offer custom sizes when needed.

-

Envelope and Mailer Sizes

Envelopes and mailers also have standard sizes. Small mailers are used for books. Large ones are used for clothes. We design them to fit the product and protect it. Mailers help with light shipping. They are easy to carry and store. We make padded mailers for fragile items. Our team picks the best size for each product.

-

Pallet and Bulk Packaging

Pallets carry many boxes. Their size must match the boxes. Bulk packaging uses big boxes for many items. We use standard sizes to save space and reduce costs. Bulk boxes help with wholesale orders. Pallets make shipping faster. We design them to fit trucks and shelves. Our experts use smart layouts for bulk packaging.

Smart Tips for Businesses

Always measure your product first. Then choose the box size.

Use the correct order: Length × Width × Height

Check both internal and external dimensions. It makes your product safe and presentable. Ask for help if you’re unsure. Our team gives free advice. We also offer samples to test fit. Choosing the right box helps your brand grow. Use strong materials for heavy items. Pick light boxes for small goods. Always label the size clearly. Our supportive team helps you avoid mistakes.

Conclusion

Dimensions are more than numbers. They help your product fit, stay safe, and look great. When you use the right size, your brand looks professional. Your customers stay happy. Boxes that fit well protect your items. They also save money on shipping. Our team works hard to get every size right. We care about your business. Our company knows how to measure and design boxes the right way. We use the length, width and height dimensions to make packaging that works. You should buy the boxes from Blackline Packaging to enhance your brand and protect your products.

Frequently Asked Questions

We've answered all the common questions you may have before ordering a custom box.

What is the correct order of length, width, and height?

Normal configuration is Length Width Height, length being usually the longest side.

How do I know which side is length and width?

The frontal side is the longest side, and the rear side is the shortest side.

Are box dimensions measured inside or outside?

Box sizes will usually be brought indoors to ensure that the products fit.

Why are dimensions important in packaging?

Proper measurements help in the security of the product, the cost of shipping and the brand image.

Can I use cm instead of inches for dimensions?

Yes, either of the two is fine; both will be under the same measurement system.

What tools are best for measuring box dimensions?

A tape measure, ruler or digital caliper is the best tool to utilize in order to make accurate measurements.

How do I measure irregular or round packaging?

Take the widest length, width and height and get the right dimensions.

What’s the difference between dimensional weight and actual weight?

Actual weight is the actual weight of the product, and dimensional weight is computed on the space occupied by the product in shipping.