Milk cartons are used every day. They hold milk in homes, schools, and stores. These cartons come in many sizes. Some are small, like half-pint cartons of milk. Others are big, like a half-gallon milk carton. Each carton has a special shape and size. Knowing how to measure milk carton sizes and dimensions is very helpful. It helps in making cartons that fit well. When cartons are the right size, they look better and work better.

Blackline Packaging makes durable and functional custom bulk milk carton boxes. We use smart tools and easy steps to measure each carton. This helps us make strong and neat packaging. We also help other companies with their packaging needs. In this blog, we are discussing how to measure milk carton dimensions. We will explain the tools, steps, and formulas used to get the right size. You’ll learn how to measure each part and calculate the volume.

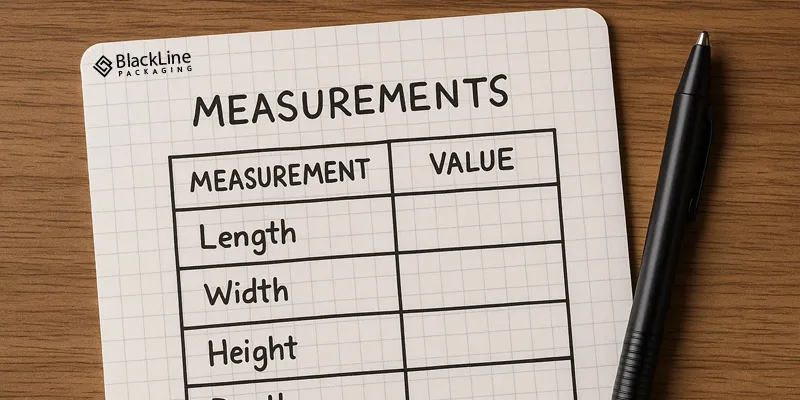

Understanding The Key Dimensions

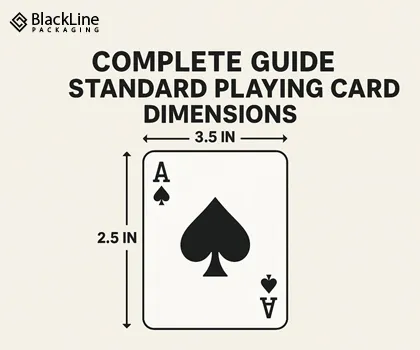

Despite their seeming simplicity, milk cartons are made up of numerous elements. We must comprehend their shape to measure them. The majority of cartons have a pointed top and a box-like form. We refer to this top as a gable. There are three major sides to each carton. We can determine how much room the container requires thanks to these sides. They also aid in the design of cartons that are compatible with boxes and shelves.

The first step in determining the proper size is to measure these sides. Our packaging experts use these measurements to create perfect cartons. Whether it’s a paper pint milk carton or a quart milk carton, the shape matters. Accurate dimensions help in stacking and storing.

Three Core Linear Measurements

-

Length (or Depth)

Length is the front-to-back side of the carton. It shows how deep the carton is. This helps in placing cartons in rows. It also helps in designing cartons that fit in shelves and boxes. Length is important when cartons are packed together. If the length is wrong, cartons may not fit well. Measuring depth helps in making cartons that are easy to handle. Our team uses this measurement to design cartons that work well in shipping boxes. It helps in saving space and keeping cartons safe.

-

Width

Width is the side-to-side part. It tells how wide the carton is. This is important when cartons are packed together. If the width is wrong, cartons may not fit well in cardboard boxes. Width helps in stacking cartons neatly. It also helps in designing cartons that look good. This helps in safe transport and storage.

-

Height

Height is how tall the carton stands. It includes the body and the gable top. Some cartons have tall gables. Others have short ones. Measuring height helps determine how much space the carton occupies. Height is important for shelf space. It also affects the amount of milk the carton can hold. Measuring height helps in designing cartons that are easy to pour from. We use height to make cartons that are user-friendly and safe. It helps in creating cartons that match your brand’s needs.

Volume vs. Dimensions: What’s the Difference?

-

Dimensions (LxWxH)

Dimensions are the outside measurements. They help in making cartons that fit in shipping boxes. They also help in stacking cartons neatly. Dimensions are used to design the shape of the carton. They help in making cartons that look good and work well. These measurements are key in packaging design. Blackline Packaging uses dimensions to create cartons that match your product needs. Whether it’s a small or large carton, the shape matters.

-

Volume (Capacity)

Volume is the space inside the carton. It tells how much milk the carton can hold. For example, a quart of milk cartons holds more than a paper pint milk carton. Volume is measured in ounces or liters. Volume helps in knowing how much product fits inside. It’s important for filling and sealing. Measuring volume helps in making cartons that hold the right amount. We use volume to design cartons that are efficient and safe.

Essential Tools And Preparation

We need the right tools and a clean space. This helps in getting accurate numbers. Having the right tools makes measuring easy. It also helps in avoiding mistakes. A clean surface helps in keeping the carton steady. Our team uses these tools to make sure every carton is perfect. We follow simple steps to get the right size every time.

Required Tools

- Ruler

A ruler helps in measuring small cartons. It gives straight lines and clear numbers. It’s easy to use and carry. We use rulers for paper pint milk cartons. They help in getting quick and simple measurements. Rulers are great for flat surfaces. Our team uses rulers to check width and length. They help in making cartons that fit well.

- Measuring tape

A tape is good for bigger cartons. It bends and wraps around the carton. It gives flexible measurements. A measuring tape helps in checking depth and height. It’s useful for half-gallon milk cartons. It’s easy to use and store. We use tape to measure cartons that are tall or wide. It helps in getting full measurements.

- Digital caliper

A caliper gives exact numbers. It’s good for small parts. It shows measurements in decimals. Calipers help in measuring edges and corners. They are great for detailed work. They give very accurate results. Our company uses calipers for custom bulk milk carton boxes. They help in making perfect designs.

- Pen and paper for recording measurements

Writing down numbers helps in keeping track. It avoids mistakes. It’s easy and quick.

We use paper to record each step. It helps in checking and comparing. It’s useful for planning. Our team uses notes to design cartons that match your needs. It helps in making smart choices.

- Flat surface to ensure accurate readings

A flat table keeps the carton steady. It helps in getting straight lines. It avoids errors.

We use flat surfaces for all measurements. It helps in keeping tools steady. It makes the process smooth. Our company uses clean tables for measuring. It helps in getting perfect results.

Measurement Standards

- Choosing a single unit (Inches or Centimeters): Using one unit keeps things simple. It helps in comparing sizes. It avoids confusion.

We choose inches or centimeters based on your needs. It helps in making cartons that match your market. It’s easy to convert if needed.

- Understanding the need for decimal precision (e.g., 1/16th of an inch or 0.1 cm):

We use decimals for detailed work. It helps in making cartons that seal well. It avoids leaks and spills.

Our company uses precision to make strong and safe cartons. It helps in building trust with customers.

Step-by-Step Measurement for Rectangular Base Dimensions (W & D)

The bottom portion of the carton is called the base. On a table, it is flat. First, we measure this section. This makes it easier to determine how much room the carton requires. Using a tape or ruler to measure the foundation is simple. It gives the width and depth. These numbers help in designing the carton shape. Our team uses these steps to make cartons that fit well in cardboard boxes. It helps in safe packing and shipping.

Measuring the Width (W)

Write down the number. This is the width. It helps in knowing how wide the carton is. Width helps in stacking cartons side by side. It also helps in designing labels and prints. Measuring width is the first step in carton design. We use width to make cartons that look neat and fit well. It helps in saving space and improving storage.

Measuring the Depth/Length (D)

Now measure from the front to the back. This is the depth or length. Use the tape or ruler. Keep the carton steady. Write down the number. This helps in knowing how deep the carton is. Depth helps in placing cartons in rows. It also affects how much milk the carton can hold. Measuring depth is easy and quick. Our team uses depth to design cartons that are easy to handle. It helps in making cartons that work well in stores.

Measuring the Height (H) – Handling Gable Tops

Some cartons have a pointed top. This is called a gable. We need to measure both the full height and the parts. Measuring height is important for shelf space. It also affects pouring and sealing. We use height to make cartons that are user-friendly. Our company designs cartons with the right height for each use. It helps in making cartons that match your brand.

Measuring the Total Height (HTotal)

Measure from the bottom to the very top. This gives the total height. Use a ruler or tape. Make sure the carton is straight. Write down the number. Total height includes the body and the gable. It helps in knowing the full size. It’s useful for packing and stacking. We use total height to make cartons that fit well in corrugated boxes. It helps in safe transport.

Isolating the Body Height (HBody)

Now measure just the body. This is from the bottom to where the gable starts. This part holds most of the milk. Write down the number.

Isolating the Gable Height (HGable)

Calculation: HGable = HTotal − HBody

This gives the height of the gable part. It helps in knowing how much space the top part takes.

Calculating Internal Volume (Relating Dimensions to Capacity)

.webp)

We use formulas for this. This helps in making cartons that hold the right amount.

Calculating the Rectangular Prism Volume (VBody)

Use this formula: Volume = Width × Depth × Body Height (W × D × HBody)

This gives the volume of the main box part. It helps in knowing how much milk fits in the body.

Calculating the Gable Volume (VGable)

The gable is like a triangle. Use this formula: Volume = 0.5 × Width × Gable Height × Depth (V = 0.5 × W × HGable × D)

This gives the volume of the top part. It helps in knowing how much extra space is there.

Total Measured Volume

Add both volumes together: VTotal = VBody + VGable

This gives the full volume of the milk carton.

Why Accurate Measurements Matter

Blackline Packaging makes custom bulk milk carton boxes. We use exact measurements to make sure each carton is perfect. This helps in storing and shipping milk cartons for sale. It also helps in designing cartons that look good and work well. When cartons are measured correctly, they fit better in cardboard boxes. They also stack neatly in corrugated boxes. This saves space and keeps things safe during transport.

Real-Life Examples of Carton Sizes

Let’s look at some common carton sizes. These are used in homes, schools, and stores. A half pint carton of milk is small. A quart of milk cartons is bigger. It holds 32 ounces. A half gallon milk carton is even bigger. It holds 64 ounces. Each of these has different dimensions. But they all follow the same measuring steps. Our packaging team uses these steps to make sure every carton is just right.

How Blackline Packaging Ensures Precision

We check every carton carefully. We also test them to make sure they hold the right amount of milk. We offer custom bulk milk carton boxes for all needs. Whether you need small cartons or big ones, we’ve got you covered. We also provide milk cartons for sale in different sizes.

Tips for Measuring at Home or Work

If you want to measure cartons yourself, follow these tips.

- Use a flat table.

- Verify that the box is empty.

- Make use of tape or a ruler with distinct marks.

- Put each number on paper.

- Check your work again.

- We walk you through the procedure.

- We also offer samples and templates.

- This makes it easy to get started.

Conclusion

From small paper pint milk cartons to big half gallon milk cartons, each one needs care and precision. Our company provides the best packaging solutions. We offer custom designs, strong materials, and expert help. You should buy your cartons from Blackline Packaging to make your brand stand out and keep your milk fresh.

Frequently Asked Questions

We've answered all the common questions you may have before ordering a custom box.

What are the dimensions of a milk carton?

A standard size milk carton dimensions are usually around 9 x 9 x 24 cm.

How to calculate carton box dimensions?

You can calculate it by multiplying the carton’s length, width, and height.

What measure is used to measure milk in a carton?

Milk in a carton is measured in liters or milliliters.

What are the dimensions of a 2L milk carton?

A 2L milk carton typically measures around 10 x 10 x 26 cm.

How do you measure a carton?

The carton can be measured by length, width and height, and will typically be in some standard unit, like a ruler or measurement tape.

What is carton length?

The length of the carton is considered the longest side of the box, from front to back.

What are the dimensions of a 2 liter?

A 2 liter container measures about 10 cm x 10 cm x 26 cm.

How tall is a milk carton in centimeters?

A standard milk carton is about 24 to 26 centimeters tall.

How tall is a 4 litre milk jug?

A 4 liter milk jug is approximately 30 to 32 centimeters tall.

What is the formula for the dimensions of a box?

The formula is Length × Width × Height = Volume.